The seal of the solenoid valve includes two kinds of seals to prevent internal leakage and seals to prevent external leakage. It means that the sealing pair contacts and under the action of external force, the sealing material produces elastic and plastic deformation, so that the gap between the sealing pairs is filled and blocked. ability to leak.

In order to ensure that the minimum pressure per unit area of the sealing part of the sealing pair required for sealing is called the necessary specific pressure, the necessary specific pressure must be guaranteed during design. The necessary specific pressure depends on the sealing material (rubber, plastic, metal), the working medium (water, gas, oil, steam), the working pressure, the sealing width and the positional accuracy and quality of the surface shape.

The leakage amount of the solenoid valve is a main performance index that characterizes the sealing performance of the valve. The factors that usually affect the sealing performance of the valve mainly include the following items.

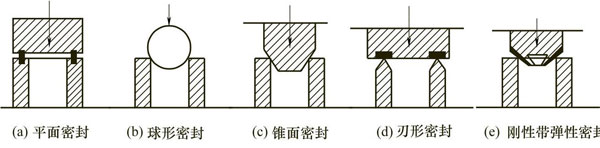

1. Sealing structure The sealing structure of the solenoid valve includes flat seal, spherical seal, conical seal, blade seal and rigid seal with elastic sealing surface (Figure 1).

Figure 1 Solenoid valve sealing structure

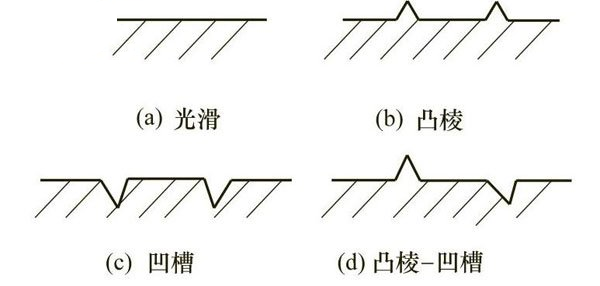

2. The shape of the sealing surface The sealing surface of the solenoid valve has a smooth microscopic surface, ridges, grooves and ridges-grooves (Figure 2).

Fig. 2 Surface shape of solenoid valve

3. The size of the leakage of the sealing medium pressure has a nonlinear relationship with the medium pressure difference, that is,

Q leak=M(NΔp2+SΔp)

In the formula, M, N, S——the processing quality and sealing of the sealing surface of the material

The sealing specific pressure value and other conditions on the surface

The relevant fixed coefficients.

4. The width of the sealing surface should be reduced proportionally with the increase of the width of the sealing surface under the premise that the necessary sealing specific pressure is guaranteed. But in fact, the entire width may not act as a seal to the same extent, and sometimes it may cause leakage.

5. Due to the different viscosity and permeability of gas, liquid and oil medium, the type of sealing medium has different leakage.

6. The shape and position deviation of the sealing surface The unevenness, parallelism, perpendicularity and surface roughness of the sealing surface have an impact on the sealing leakage.

The leakage is inversely proportional to the sealing specific pressure of the sealed surface, that is, the larger the selected sealing specific pressure is compared with the necessary specific pressure, the more the leakage is reduced and the better the sealing performance is.

From the life test of the number of actions of the valve, it mainly tests the mechanical wear and elastic deformation of the product. After the wear, the performance indicators specified in the product standard should still be guaranteed. In order to improve the life of the number of actions, the sealing surface selection should be closer to the necessary ratio. Pressure, that is, under the condition of ensuring sealing, the smaller the elastic deformation of the sealing pair, the better the working state and the longer the life, so there is a contradiction between the sealing and the life.

In general, rubber parts or plastic parts with higher Shore hardness are used for the soft seal of the motion seal pair of the solenoid valve, and metal materials with a large elastic modulus are used for the rigid seal. In theory, high sealing specific pressure is beneficial to the sealing of the valve, but for the operating life of the valve, the larger the sealing specific pressure is, the closer the material is to the allowable specific pressure for extrusion, the sealing material will be deformed greatly, and fatigue is likely to occur. Or damage, will greatly reduce the number of action life. Solution In order to avoid edge sealing, use smooth arc shape or bevel shape or overload limit protection method. As the medium pressure increases, the contact seal width gradually increases, so that the increase in the specific pressure of the seal is slow, and it is still squeezed eventually. The pressure is within the limit of the allowable specific pressure, which not only exerts a good sealing effect but also prolongs the action life of the sealing pair.